Company News

The Technical Principles and Applications of Supercritical Extraction

Release time:2024-05-23

1. The technical principle of supercritical extraction

The relationship between the solubility of the supercritical fluid and its density is used, that is, the influence of pressure and temperature on the solubility of the supercritical fluid is used. In the supercritical state, the supercritical fluid is in contact with the substance to be separated, so that the components of polarity, boiling point and molecular weight are selectively extracted in turn.

Of course, the extractables obtained corresponding to each pressure range cannot be single, but the conditions can be controlled to obtain the optimal proportion of mixed components, and then with the help of decompression and temperature raising methods, the supercritical fluid becomes an ordinary gas, and the extracted substances are completely or basically precipitated, so as to achieve the purpose of separation and purification, so the supercritical CO2 fluid extraction process is composed of a combination of extraction and separation process.

Supercritical CO2 refers to a compressible high-density fluid in a state above the critical temperature and critical pressure (called the critical point), which is the fourth state other than the gas, liquid and solid states, and its intermolecular force is very small, similar to gas, but the density is very large, close to liquid, so it has the dual properties of gas and liquid between gas and liquid, and has higher solubility of liquid and higher fluidity of gas, higher mass transfer rate than ordinary liquid solvents, and the diffusion coefficient is between liquid and gas. It has good permeability and no interphase effect, so it helps to improve the extraction efficiency and can greatly save energy.

The physicochemical properties of supercritical CO2 are very different from those of liquids and gases in the noncritical state. Since density is the solubility capacity, viscosity is the fluid resistance, and diffusion coefficient is the main parameter of mass transfer rate, the special properties of supercritical CO2 determine that supercritical CO2 extraction technology has a series of important characteristics.

The viscosity of supercritical CO2 is one percent of that of liquid, and the self-diffusion coefficient is 100 times that of liquid, so it has good mass transfer characteristics, which can greatly shorten the time required for phase equilibrium, and is an ideal medium for efficient mass transfer. It has a much faster rate of dissolving solutes than liquids, and has a much greater ability to dissolve and carry solid substances than gases; It has an unusually large compressibility, and a small change in pressure and temperature will cause a large change in the density of CO2 at the critical point, so the solubility of CO2 can be adjusted by simply changing the temperature or pressure of the system to improve the selectivity of extraction; By reducing the pressure of the system, CO2 and dissolved products are separated, eliminating the need to eliminate solvents.

In traditional separation methods, solvent extraction takes advantage of the difference in affinity (manifested in solubility) between the solvent and each solute to achieve separation; Distillation takes advantage of the difference in the volatility (vapor pressure) of the components in the solution to achieve separation. Supercritical CO2 extraction is separated by adjusting the pressure and temperature of CO2 to control the solubility and vapor pressure, so supercritical CO2 extraction combines the two functions and characteristics of solvent extraction and distillation.

Supercritical CO2 extraction has advantages that traditional ordinary fluid extraction methods do not have: it can easily change the properties of the solvent by adjusting the pressure and temperature to control its selectivity; Appropriate selection of extraction conditions and solvents, can operate at close to room temperature, and can be applied to heat-sensitive substances; Due to the small viscosity and large diffusion coefficient, the extraction speed is fast; The separation of solutes and solvents is thorough and easy. Judging by its characteristics and completeness, it is equivalent to a new unit operation, so it has attracted widespread attention at home and abroad.

2. Characteristics of supercritical extraction

1. Supercritical extraction can be extracted at close to room temperature (35~40 °C) and under the hood of CO2 gas, which effectively prevents the oxidation and escape of heat-sensitive substances. Therefore, the active ingredients of medicinal plants are maintained in the extract, and the substances with high boiling point, low volatility and easy pyrolysis can be extracted at a temperature far below their boiling point.

2. The use of SFE is the cleanest extraction method, because the whole process does not use organic solvents, so the extract has no residual solvent substances, so as to prevent the existence of harmful substances to the human body and pollution to the environment in the extraction process, to ensure 100% naturalness;

3. Extraction and separation are combined into one, when the CO2 fluid of saturated dissolved matter enters the separator, due to the drop of pressure or the change of temperature, the CO2 and the extract quickly become two phases (gas-liquid separation) and immediately separated, which not only has high extraction efficiency and less energy consumption, improves production efficiency and reduces costs;

4. CO2 is an inactive gas, no chemical reaction occurs during the extraction process, and it is a non-flammable gas, tasteless, odorless, non-toxic, and very good safety;

5. CO2 gas is cheap, high purity, easy to produce, and can be recycled in production, thus effectively reducing the cost;

6. Pressure and temperature can be used to regulate the parameters of the extraction process, and the purpose of extraction can be achieved by changing the temperature and pressure, and the fixed pressure can also separate the substances by changing the temperature; Conversely, the temperature is fixed and the extracts are separated by reducing the pressure, so the process is simple and easy to master, and the extraction speed is fast.

3. The superiority of supercritical CO2 extraction technology in the modernization of traditional Chinese medicine

1. Strong extraction ability and high extraction rate. The extraction of the active ingredients of traditional Chinese medicine with supercritical CO2 can almost completely extract the required extracted components under the optimal process conditions, thereby greatly improving the product yield and resource utilization. At the same time, with the continuous progress of supercritical CO2 extraction technology, supercritical CO2 extraction has been extended to aqueous solution system, which has made it possible to extract supercritical CO2 from highly polar compounds such as proteins that are difficult to extract.

2. The magnitude of the extraction capacity depends on the density of the fluid, and ultimately on the temperature and pressure of the operating process. Changing one of them or changing at the same time can change the solubility, and the separation of a variety of substances in traditional Chinese medicine can be selectively carried out, so as to reduce impurities, make the active ingredients of traditional Chinese medicine highly enriched, facilitate the reduction of dosage and control of quality, and greatly improve the appearance of the product;

3. The operating temperature of supercritical CO2 extraction is low, and the active ingredients of traditional Chinese medicine can be preserved relatively well without being destroyed and secondary biochemistry occurring, so it is especially suitable for the extraction of components that are sensitive to heat and easy to be destroyed by oxidative decomposition;

4. The extraction time is fast and the production cycle is short. As soon as the supercritical CO2 extraction cycle begins, the separation begins. Generally, the components are separated and precipitated in 10 minutes, and can be completely extracted in about 2~4 hours, at the same time, it does not need to concentrate and other steps, even if the entrainment agent is added, it can be removed by the separation function or simply concentrated;

5. Supercritical CO2 extraction, the operating parameters are easy to control, so it can ensure the stability of the active ingredients and product quality;

6. Supercritical CO2 can also be directly extracted from single or compound Chinese medicine to extract different parts or extract extract for pharmacological screening, develop new drugs, and greatly improve the screening speed of new drugs. At the same time, it can extract many substances that cannot be extracted by traditional methods, and it is easier to discover new ingredients from traditional Chinese medicine, so as to discover new pharmacological properties and develop new drugs;

7. Supercritical CO2 also has antioxidant and sterilization effects, which is conducive to ensuring and improving the quality of products;

8. Supercritical CO2 extraction is used for analysis or combined with GC, IR, MS, LC, etc. to become an efficient means of analysis, which can be used for quality analysis of traditional Chinese medicine, which can objectively reflect the true content of active ingredients in traditional Chinese medicine;

9. It has been pharmacologically and clinically proven that supercritical CO2 extraction of traditional Chinese medicine is not only superior in technology, stable in quality, but also easy to control in standard, and its pharmacological and clinical effects can be guaranteed or better;

10. The supercritical CO2 extraction process is simple, easy to operate, saves labor and a large number of organic solvents, and reduces the pollution of the three wastes, which undoubtedly provides a new method of efficient extraction, separation, preparation and concentration for the modernization of traditional Chinese medicine.

- View details + Previous Article What is supercritical extraction

- View details + Next article No next article

Hot products

-

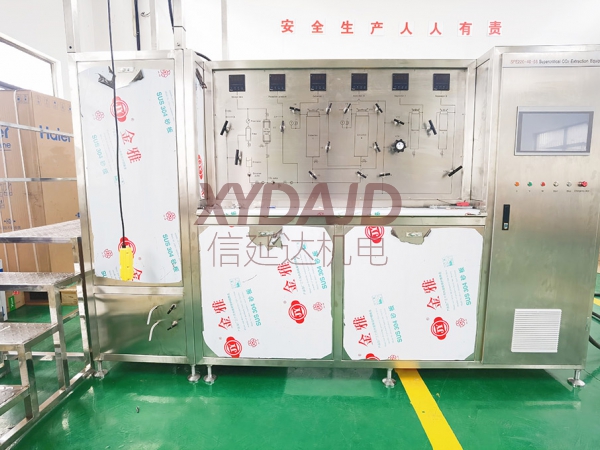

87L (29Lx3) supercritical CO2 extraction device

-

90L (30Lx3) supercritical CO2 extraction device

-

5L supercritical CO2 extraction device

-

56L (28Lx2) supercritical CO2 extraction device

-

Indoor evaluation device for formation damage caused by drilling and completion

-

Heavy oil hydrogenation reaction device

Service Hotline

Service Hotline