Company News

What is supercritical extraction

Release time:2024-05-23

The supercritical fluid extraction process is a new chemical separation technology developed by using the specific increase in the solubility of the fluid above the critical low pressure and the critical temperature, and it is found that the phenomenon of increasing the dissolution of organic compounds by the fluid above the critical pressure and critical temperature is very amazing. Generally, it can be increased by several orders of magnitude, and under the right conditions, it can even reach 1010 times the concentration calculated by vapor pressure (solubility of oleic acid in supercritical ethylene), but the supercritical fluid extraction process, a new separation technology with this special solubility ability, has been in the past 20 years. Since the 80s, a lot of manpower and material resources have been invested in research, covering food, spices, medicine and chemical industries, and a series of progress has been made. The research of supercritical fluid extraction in China began in the early 80s of the 20th century, and has gradually developed from the aspects of basic data, process flow and experimental equipment, and after more than 20 years of efforts, the research and application of supercritical fluid extraction technology in China has made remarkable achievements. At present, more than 10 sets of industrial-scale extraction devices and more than 100 sets of small and medium-sized equipment have been built across the country. Supercritical fluid extraction has gradually moved towards industrialization in China, and a variety of products have entered the market, and its development is in the ascendant.

1 Introduction to the Supercritical Fluid Extraction Process

The extraction raw material is loaded into the extraction kettle. Carbon dioxide is used as a supercritical solvent. The carbon dioxide gas is condensed into a liquid by a heat exchanger, and the pressure is raised to the pressure required for the process (which should be higher than the critical pressure of carbon dioxide) by a pressurized pump, and the temperature is adjusted to make it a supercritical carbon dioxide fluid. The carbon dioxide fluid enters from the bottom of the extraction kettle as a solvent and is in full contact with the extracted material to selectively dissolve the desired chemical components. The high-pressure carbon dioxide fluid containing the dissolved extract is depressurized below the critical pressure of carbon dioxide through the throttle valve and enters the separation kettle (also known as the analysis kettle), and the solute is precipitated due to the sharp decline in carbon dioxide solubility, and is automatically separated into two parts: solute and carbon dioxide gas, the former is a process product, which is regularly released from the bottom of the separation kettle, and the latter is a circulating carbon dioxide gas, which is condensed into a carbon dioxide liquid through a heat exchanger and recycled. The whole separation process is to take advantage of the carbon dioxide fluid in the supercritical state to increase the solubility of organic matter, and below the critical state is basically insoluble to organic matter, the carbon dioxide fluid is continuously circulated between the extraction kettle and the separation kettle, so as to effectively separate the components that need to be separated and extracted from the raw materials.

2 Characteristics of supercritical fluid extraction technology

2.1 Wide adaptability

Due to the phenomenon of specific increase in solubility of supercritical fluids, it is common. Therefore, supercritical fluid extraction technology can theoretically be applied as a general and efficient separation technology.

2.2 High extraction efficiency and easy adjustment of the process

Supercritical fluid has both gas and liquid characteristics, so supercritical fluid has both liquid dissolution ability and good gas flow and transmission performance. And near the critical point, small changes in pressure and temperature have the potential to significantly alter the fluid's solubility and control the separation process.

2.3 Simple separation of process fluid

Supercritical extraction is only composed of two parts: extractor and separator, and does not require solvent recovery equipment, which not only simplifies the process compared with the traditional separation process, but also saves energy.

2.4 The separation process may be completed at close to room temperature (carbon dioxide), especially for allergenic natural products

2.5 It must be operated under high pressure, the equipment and process technology requirements are high, and the investment is relatively large

3 Prospects for

supercritical fluid extraction technology Nowadays, with the continuous improvement of people's living standards, the general concern about industrial pollution, and the trend of increasingly stringent food management and hygiene regulations around the world, natural products and "green food" will continue to develop. However, the traditional natural product separation, refining processing technology in the pressing; Heating; Process methods such as water vapor distillation and solvent extraction often cause some heat-sensitive or chemically unstable components in natural products to be destroyed during processing, changing the unique "flavor" and nutrition of natural foods. Moreover, the contamination of solvent residues in the processing process is also unavoidable, so people have been looking for new natural product processing processes, and supercritical fluid extraction technology will be able to meet this requirement. Therefore, in the past 20 years, a lot of research work has been invested in the field of supercritical fluid extraction and separation. And in the field of food and spice processing, a number of valuable application results have been obtained, which have attracted widespread attention. However, supercritical fluid extraction has not replaced the traditional separation method as some people expect, especially since the 90s, the development trend has slowed down, and there is no new, influential industrial achievements.

(2) The extraction kettle cannot be operated continuously, resulting in a relatively low spatiotemporal generation rate of the device.

(3) The process consumption index cannot be ignored.

Therefore, the development of supercritical fluid extraction technology should fully consider its economic performance, and only those processes that can give full play to the inherent advantages of the technology have industrial practicability, which is gradually becoming a consensus.

China's supercritical extraction technology has gone through the stages of introduction and imitation of equipment and process technology, and has gradually moved towards industrialization. In addition, how to go to the market of supercritical products in China at present, is also a major issue of whether the technology can be further developed, and it is earnestly hoped that with the efforts of the national counterparts, China's supercritical fluid extraction industry can form characteristics and walk out of a way of its own.

- View details + Previous Article Supercritical extraction equipment is widely used in fields such as medicine, fo

- View details + Next article The Technical Principles and Applications of Supercritical Extraction

Hot products

-

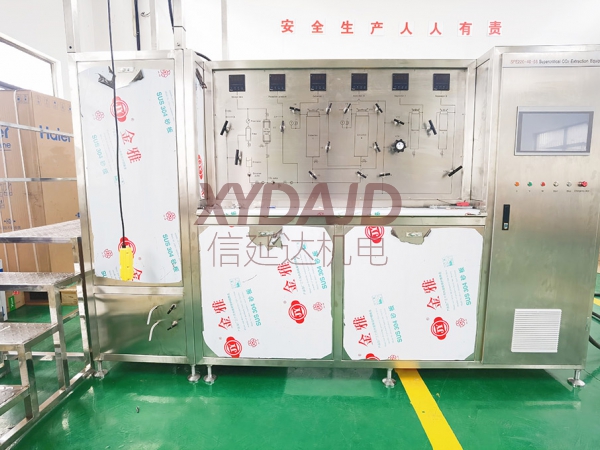

87L (29Lx3) supercritical CO2 extraction device

-

90L (30Lx3) supercritical CO2 extraction device

-

5L supercritical CO2 extraction device

-

56L (28Lx2) supercritical CO2 extraction device

-

Indoor evaluation device for formation damage caused by drilling and completion

-

Heavy oil hydrogenation reaction device

Service Hotline

Service Hotline